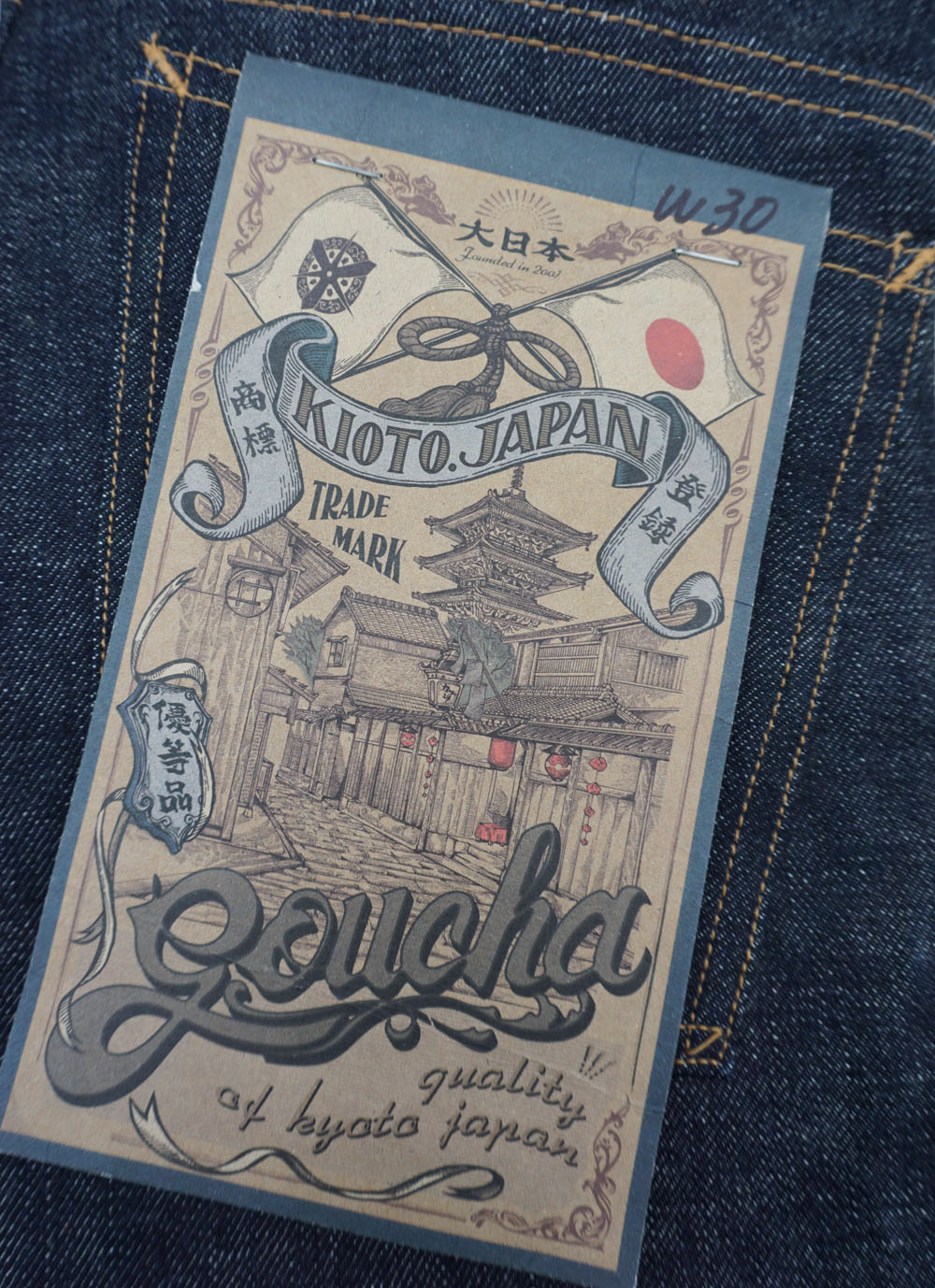

Close up - Ripping and shredding

Worn out and worn in. Warp threads are cut to partially reveal the body beneath. Stained and tinted to increase the aspect of age. Although the areas of ripping and shredding may seem random they are in fact carefully selected to work with the shape of the jean and the attitude of the brand or wearer.

Threadbare - frayed use of clean cotton or old tinted weft - hand stitching, age worn burnt edges. Double cloth is torn to reveal the reverse side or to create its own pattern.

HOW TO: Take a razor blade, cut through the warp threads on the surface. Wash to fluff the cotton and cut off unwanted threads. This should leave weft threads visible but no gaping hole. If a gaping hole is required then cut throughout the weft threads as well. You may have to machine stitch around the sedges of a complete hole to prevent further tearing in the weft direction.